ELECTRICFIELD apart from being professionally managed through academically trained persons. It is well Equipped in terms of plants and machineries, testing equipmants as under and well planned out building / site covering more than 30,000 sq/ft at industrial area phase-II, Gangyal, Jammu - 180 010.

click on image to view Advantage Fabricated Metals performs a number of Welding processes. The two most common welding processes we use include TIG, an acronym for Tungsten inert Gas welding and MIG, an acronym for Metal Inert Gas welding. TIG is also referred to as GTAW (Gas Tungsten Arc Welding) and Heliarc(R). MIG also is referred to as GMAW (Gas Metal Arc Welding). We also provide oxy-acetylene welding. The "Metal" in Gas Metal Arc Welding refers to the wire that is used to start the arc. It is shielded by inert gas and the feeding wire also acts as the filler rod. MIG is fairly easy to learn and use as it is a semi-automatic welding

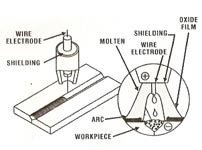

process. The illustration that follows provides a look at a typical MIG welding process showing an arc that is formed between the wire electrode and the work piece. During the MIG welding process, the electrode melts within the arc and becomes deposited as filler material. The shielding gas that is used prevents atmospheric contamination from atmospheric

contamination and protects the weld during solidification. The shielding gas also assists with stabilizing the arc which provides a smooth transfer of metal from the weld wire to the molten weld pool.

Advantage Fabricated Metals performs a number of Welding processes. The two most common welding processes we use include TIG, an acronym for Tungsten inert Gas welding and MIG, an acronym for Metal Inert Gas welding. TIG is also referred to as GTAW (Gas Tungsten Arc Welding) and Heliarc(R). MIG also is referred to as GMAW (Gas Metal Arc Welding). We also provide oxy-acetylene welding. The "Metal" in Gas Metal Arc Welding refers to the wire that is used to start the arc. It is shielded by inert gas and the feeding wire also acts as the filler rod. MIG is fairly easy to learn and use as it is a semi-automatic welding

process. The illustration that follows provides a look at a typical MIG welding process showing an arc that is formed between the wire electrode and the work piece. During the MIG welding process, the electrode melts within the arc and becomes deposited as filler material. The shielding gas that is used prevents atmospheric contamination from atmospheric

contamination and protects the weld during solidification. The shielding gas also assists with stabilizing the arc which provides a smooth transfer of metal from the weld wire to the molten weld pool.

Characteristics of the MIG welding process

Versatility is the major benefit of the MIG welding process. It is capable of joining most types of metals and it can be performed in most positions even though flat horizontal is most optimum.

The most common welds include the Butt Joint, Lap Joint, Edge Joint, T-Joint.

|

Butt Joint |

Lap Joint |

T-Joint |

Edge Joint |

MIG is used to weld many materials, and different gasses are used to form the arc depending on the materials to be welded together. An argon CO2 blend is normally used to weld mild steel, aluminum, titanium and alloy metals. Helium is used to weld mild steel and titanium in high speed process and also copper and stainless steel. Carbon dioxide is most often used to weld carbon and low alloy steels. Magnesium and cast iron are other metals commonly welded used the MIG process.

For more information about Advantage Fabricated Metals and the metal forming, metal fabricating and welding services we provide, please fill out our Contact from or call us at 1-815-323-1310.

Related Metal Fabricating Services